УДК 550.832.5.05:681.3/622.245

Я. С. Гайфуллин, В. Н. Даниленко, Р. А. Шайхутдинова, И. Т. Сиразетдинов, М. И. Ильясова

АО НПП «ВНИИГИС», АО НПФ «ГИТАС»

Рассматриваются задачи исследования обсаженных скважин на основе разработанных в АО НПП «ВНИИГИС» и АО НПФ «ГИТАС» спектрометрических методов радиоактивного каротажа, реализованных в комплексной аппаратуре КСПРК-Ш. Описана технология интерпретации скважинных материалов, основанная на петрофизическом моделировании.

В АО НПП «ВНИИГИС» и АО НПФ «ГИТАС» создан и развивается широкий спектр современных аппаратурных средств и технологий, позволяющих значительно повысить эффективность поисков, разведки и разработки нефтяных и газовых месторождений.

На основе разработанных в АО НПП «ВНИИГИС» и АО НПФ «ГИТАС» приборов и методик спектрометрического гамма-каротажа (СГК) и широкодиапазонного спектрометрического нейтронного гамма-каротажа (СНГК-Ш) созданы технологии, позволяющие решить целый ряд задач, возникающих при эксплуатации скважин и подземных хранилищ газа [5]. В настоящее время разработаны двухзондовая и трехзондовая модификации аппаратуры для проведения мониторинга разрезов в условиях обсаженных скважин.

Решение большинства промысловых задач предполагает выполнение широкого комплекса взаимосвязанных мероприятий по оценке околоскважинного пространства, детального уточнения фильтрационно-емкостных свойств (ФЕС) и литологических характеристик геологического разреза в процессе эксплуатации скважины.

Уточнение литологических характеристик отложений горных пород, вскрытых скважиной, позволяет провести:

– анализ геологического разреза для выявления пропущенных продуктивных объектов;

– выделение интервалов коллектора с повышенной проницаемостью с учетом литологических особенностей разреза для оптимизации выбора интервалов перфорации;

– выявление интервалов природных и техногенных каверн в эксплуатируемом горизонте;

– определение возможных интервалов скоплений газа за колонной;

– анализ интервалов ухудшения ФЕС, связанных с разбуханием глинистого цемента.

В отличие от скважин с открытым стволом, в обсаженных скважинах на показания аппаратуры влияет множество факторов, в том числе сложная конструкция скважинного оборудования (наличие колонн разной длины и толщины, конструктивных элементов скважины); разнообразное заполнение ствола скважины (газ, вода, техническая жидкость с различным составом и плотностью); неоднотипное заполнение затрубного пространства (чередование цементов разного вида, наличие ингибиторной жидкости за колонной).

В условиях исследований геологических особенностей горных пород при сложной конструкции скважины различные модификации радиоактивных методов исследования становятся наиболее важными источниками информации и позволяют решить следующие задачи:

– оценить характер затрубного пространства [4, 11];

– в условиях обсаженного ствола при ограниченном или отсутствующем комплексе ГИС-бурение построить объемную модель отложений, вскрытых скважиной;

– уточнить границы стратиграфических отложений;

– построить корреляционные разрезы скважин по результатам комплексного анализа объемных моделей;

– рассчитать коэффициент эффективной пористости на основе модели накопления естественных радиоактивных элементов (ЕРЭ) в поровом пространстве [8];

– выделить коллекторы, оценить насыщенность и прогнозировать проницаемость с учетом литологических особенностей коллектора;

– прогнозировать устойчивость стенок скважины в процессе бурения и эксплуатации;

– выявить переток газа в вышележащий водоносный коллектор;

– выявить техногенные скопления газа неуглеводородной природы и газа органических скоплений.

Технология интерпретации включает ряд эксклюзивных взаимосвязанных задач на основе их представления в виде интерпретационных моделей.

Актуальность использования литологических моделей для условий подземных хранилищ газа (ПХГ) и ГИС-контроля скважин связана со сложностью и неоднозначностью интерпретации разнообразной геолого-геофизической информации. При этом используется идеология петрофизического моделирования [6] на основе программы ОРТСОМ [7] в интегрированной системе ПРАЙМ (ГеоТЭК).

Петрофизическое моделирование позволяет обоснованно учитывать множество неформальной информации. Для обсаженных скважин, в силу их специфических особенностей, идеология на этой основе приобретает особую актуальность. Полный объем традиционных видов каротажа (даже при использовании материалов открытого ствола) может и отсутствовать, поэтому информация, извлекаемая из данных СГК и СНГК-Ш, становится преобладающей.

Процесс оперирования с разнотипными данными при интерпретации облегчается благодаря возможности конструировать и модифицировать алгоритмы в системе ПРАЙМ. При интерпретации, как правило, подразумевается неформальное участие интерпретатора и оперирование множеством эмпирических знаний. В его поле зрения находятся фактически все основные элементы интерпретации, влияющие на достоверность оценки объемной модели горных пород. А от этого зависит правильность принятия решений и на других этапах интерпретации.

В качестве примеров, используемых в рамках петрофизических моделей, можно привести теоретические, статистические или эмпирические связи между значениями различных коллекторских и литологических характеристик. Имеются также определенные связи объемных физических свойств горной породы или ее коллекторских и емкостных свойств (ФЕС) с некоторыми комбинациями значений измеряемых при каротаже параметров. Такие примеры приведены ниже.

Учет взаимосвязи показаний нейтронных и нейтронных гамма-методов позволяет разработать методики оценки плотностных и емкостных характеристик пород [1–3, 9, 10].

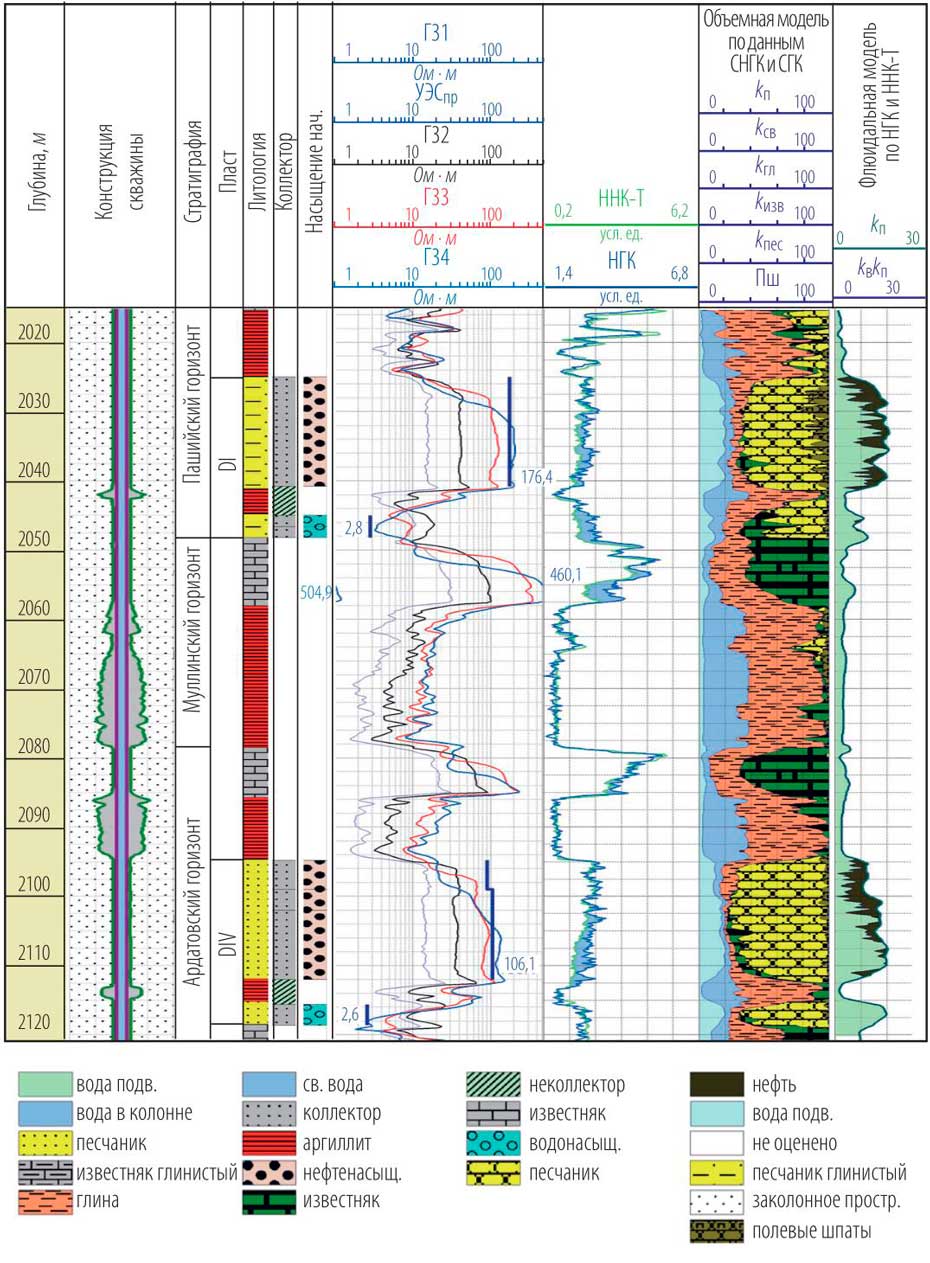

Возможность использования нейтронных методов ННК-Т и НГК для оценки насыщенности пластов на основе различия их показаний в зависимости от хлорсодержания сред обоснована в ряде работ и получила название хлорного каротажа. Наибольший эффект при этом получается при использовании области энергетического спектра, связанной с излучением хлора. С точки зрения оптимального использования физических предпосылок и их математического представления в технологии интерпретации представляет особый интерес способ, основанный на моделировании взаимосвязи показаний НГК и ННК-Т от водонасыщенности (kв) [3]. По оценке насыщенности коллекторов строится флюидальная модель. Пример построения флюидальной модели коллекторов на основе показаний ННК-Т и НГК приведен на рис. 1.

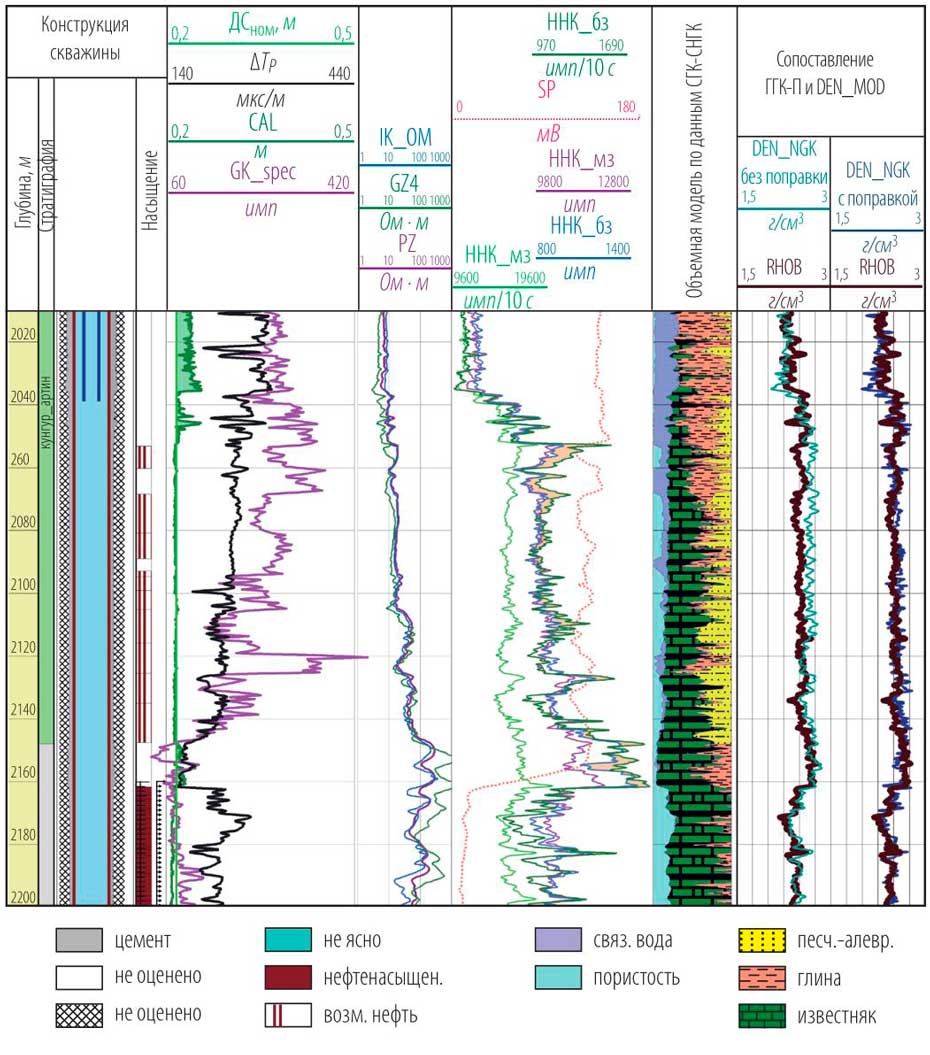

Использование показаний нейтронного гамма-каротажа для оценки плотности горных пород предполагает экспоненциальное уменьшение возникающего рассеянного гамма-излучения при удалении от источника нейтронов. В работе [2] приведена технология для данных двух детекторов гамма-квантов, соответствующих большому (БЗ), среднему (СЗ) и малому (МЗ) зондам, а также двух детекторов нейтронов, соответствующих малому и большому зондам аппаратуры СНГК-Ш. Разработан алгоритм расчета функции плотности, линейно связанной с истинной плотностью горных пород. Для этого необходимо иметь априорную информацию в виде плотностей характерных пластов (например, глины), плотных пластов или данные, полученные по ГГК-П по открытому стволу скважины. Кривая плотности (Den_mod), получаемая путем моделирования на основе объемной литологической модели, может использоваться в качестве априорной информации. На рис. 2 показан планшет с результатами оценки плотности горных пород в условиях обсаженной скважины на основе показаний НГК и ННК-Т. В разрезе присутствуют коллекторы различной насыщенности. Сопоставление плотности, полученной по НГК и ННК-Т, с плотностью, полученной в открытом стволе, показывает необходимость учета хлорсодержания коллекторов, особенно для газонасыщенных пластов (Den_ngk_с поправкой).

Корректное разделение всех взаимосвязанных факторов в общем виде является непростой задачей, и при организации технологического процесса условно рассматриваются следующие этапы:

1) учет влияния многоколонной конструкции скважины на данные, получаемые по спектрометрическим методам радиоактивного каротажа;

2) оценка физических свойств по данным ГИС, включая оценку элементного состава породы и глин по спектрометрическим методам радиоактивного каротажа (плотность, глинистость, водородосодержание, насыщенность пород).

Организацию технологии оценки объемной модели горных пород с учетом результатов подготовительных этапов можно рассматривать в виде процесса, в котором принимаются во внимание полученные промежуточные результаты. На данном этапе может использоваться как решение систем петрофизических уравнений и, при наличии возможности, как раздельное определение некоторых компонент. Полученные данные позволяют моделировать решение прямой задачи, то есть по компонентному составу рассчитать теоретические значения физических свойств горной породы. Их сопоставление с фактическими данными позволяет контролировать адекватность используемой информации. Основной информацией для данного процесса являются:

– сведения о физических свойствах горных пород (плотность, радиоактивность и ее составляющие, пористость), прогнозируемые по содержанию ЕРЭ значения эффективной пористости;

– имеющаяся петрофизическая информация о внутренних взаимосвязях компонент, что способствует повышению достоверности оценки минералогического состава при дефиците информации.

В качестве примеров, восполняющих неполноту имеющейся информации, можно привести зависимость эффективной пористости kп.эф от доли глинистого цемента, влияние карбонатизации в терригенной породе на коллекторские свойства, влияние структурных элементов в виде полевых шпатов на ФЕС пород [8]. Различными исследователями получены также статистические закономерности между составом глин и эффективной пористостью, что позволяет использовать их при оценке состава глин.

В [12] показан ряд случаев использования объемной литологической модели горных пород в процессе прогнозирования устойчивости стенок скважины и образования техногенных каверн. Спектрометрические методы радиоактивного каротажа в условиях обсаженной скважины позволяют выявить не только основные минералы горной породы, но и минералы цемента и глин, а также эффективную пористость, то есть параметры, в значительной мере определяющие физико-механические свойства горной породы [8]. Так, наибольшей прочностью характеризуются горные породы кварцевого состава, наименьшей – легкорастворимые отложения эвапоритовой формации. Кремнистые и карбонатные цементы терригенных отложений способствуют повышению прочности, глинистые – понижению. При этом состав глинистых отложений влияет на устойчивость стенок скважины не только напрямую, но и косвенно через текстуру горных пород. Например, слюдистые минералы способствуют формированию слоистой текстуры, существенно снижающей прочностные свойства горной породы.

Таким образом, информация об объемной литологической модели, рассчитанной преимущественно на основе спектрометрических методов каротажа, может быть использована при прогнозе устойчивости стенок скважины. Данная информация используется при прогнозе техногенного кавернообразования, возникающего в результате выноса материала терригенного коллектора вместе с газом в процессе эксплуатации объекта. Это приводит не только к разрушению самого коллектора, но и к ускорению износа скважинного оборудования, образованию песчаных пробок и т. д.

Техногенному кавернообразованию наиболее подвержены пласты с высокой проницаемостью, слабосцементированные и слюдистые со слоистой текстурой и повышенной неоднородностью. Следовательно, для решения задачи прогноза техногенного кавернообразования объемная модель должна отражать не только основные породообразующие составляющие (для терригенного разреза это песчаник и глина), но и состав, долю цемента, минеральный состав глинистой составляющей, долю полевошпатовых песчаников, эффективную пористость, а также тонкослоистое строение пласта. Анализ всей информации с учетом литологической модели позволяет выявить интервалы кавернообразования.

В [13] приведены некоторые характерные ситуации снижения достоверности результатов в обсаженных скважинах, связанных с неполнотой информации или ее искажением из-за геологотехнических условий измерений, такие как:

– невозможность выявления по разрезу наличия опоковидных глин, что проявляется в виде ошибочного определения ФЕС пород разреза;

– завышенные значения измеренных в скважине параметров при наличии радиационно-геохимических аномалий (РГХА);

– влияние зацементированной каверны.

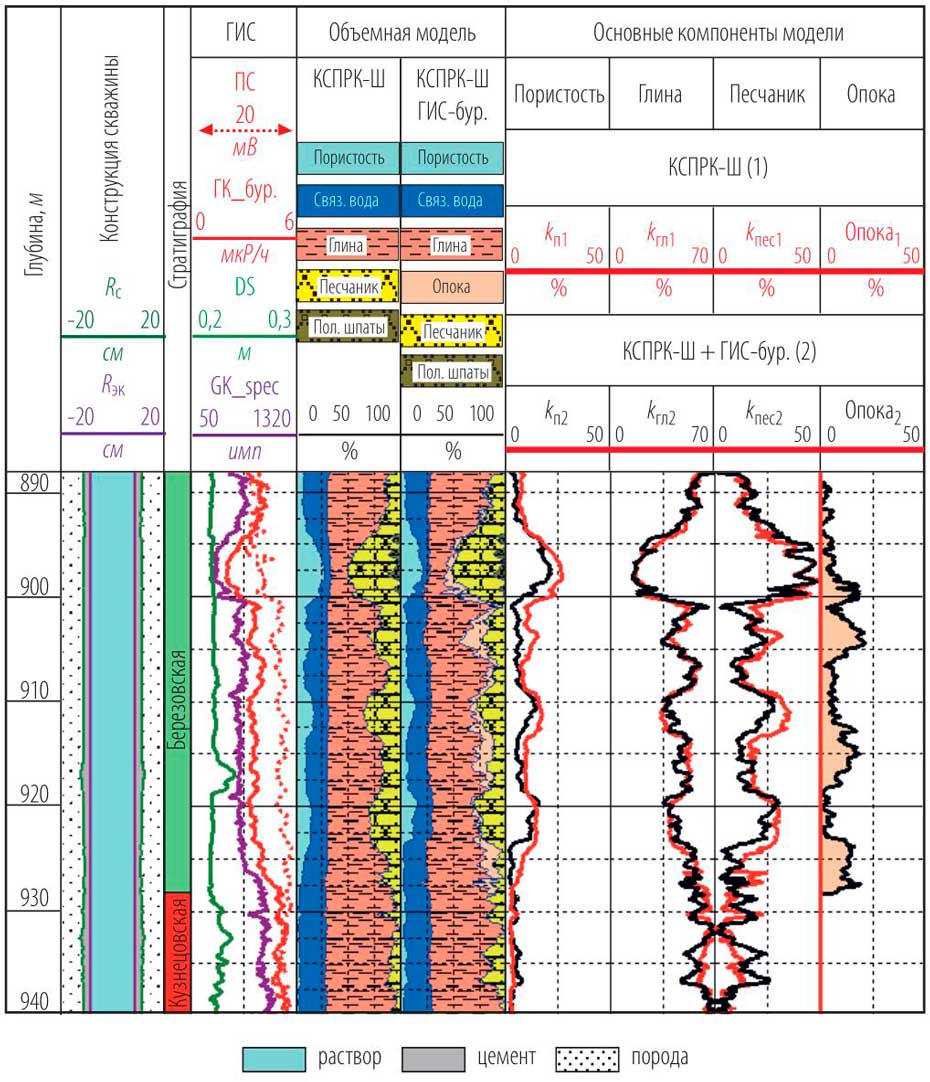

На рис. 3 представлена объемная литологическая модель, построенная по данным КСПРК, а также по данным КСПРК с учетом ГИС-бурение. Благодаря использованию петрофизической модели появляется возможность вычленить опоковидные глины из общего массива глин. Без этого учета доля кварцевого песчаника будет увеличена в среднем на 6%, что приведет к завышению пористости. В остальном модель по данным ядерных методов мало отличается от модели, полученной по данным ЯГФМ с учетом ГИС-бурения.

Основной смысл схемы учета и контроля влияния различных факторов при оценке объемной модели горных пород в условиях обсаженной скважины заключается в итеративном подборе основных параметров модели, удовлетворяющих одновременно многим критериям с учетом следующей информации:

– адекватность используемых петрофизических связей и предполагаемых компонент, что контролируется путем сопоставления теоретических и фактических значений физических свойств, используемых в петрофизических связях;

– априорные взаимосвязи между различными параметрами породы;

– априорная информация о литологии и стратиграфии;

– управление технологией интерпретации с учетом опыта интерпретатора.

Вышеописанные технологии интерпретации с ее основными элементами использованы и опробованы на материалах огромного количества скважин.

Выводы

В настоящее время основную информацию о геологическом разрезе в условиях обсаженных скважин представляют данные спектрометрических методов радиоактивного каротажа – СГК и СНГК-Ш. Разработанные в АО НПП «ВНИИГИС» и АО НПФ «ГИТАС» различные оригинальные аппаратурные комплексы позволяют решить широкий спектр сложных геолого-технических задач.

С другой стороны, в технологии использования всей совокупности получаемой геолого-геофизической и технической информации необходимо учесть многообразие их взаимосвязей. Например, значения записываемых при каротаже ядерно-геофизических данных зависят как от литологических и коллекторских характеристик, так и от геолого-технических условий измерения.

Петрофизическое моделирование способствует значительному сужению области неоднозначности неизвестных параметров и служит эффективным аналитическим средством геологических исследований, а также эксплуатационных работ в условиях обсаженных скважин.

ЛИТЕРАТУРА

- Борисов В. И., Борисова Л. К., Гулимов А. В., Зараменских Н. М. Использование широкодиапазонной спектрометрической модификации НГК для оценки плотности сред через обсадную колонну // НТВ «Каротажник». Тверь: Изд. АИС. 2006. Вып. 7–8 (148–149). С. 139–154.

- Гайфуллин Я. С., Даниленко В. Н. Оценка плотностных характеристик горных пород на основе нейтронных методов каротажа // НТВ «Каротажник». Тверь: Изд. АИС. 2020. Вып. 4 (304). С. 87–98.

- Гайфуллин Я. С., Даниленко В. Н. Опробование технологии построения флюидальных моделей коллекторов в обсаженных скважинах по данным нейтронных методов каротажа с использованием априорной информации // НТВ «Каротажник». Тверь: Изд. АИС. 2019. Вып. 4 (298). С. 18–29.

- Гайфуллин Я. С., Кожевников Д. А. Изучение состояния цемента в затрубном пространстве газовых скважин методом естественной радиоактивности // НТВ «Каротажник». Тверь: Изд. АИС. 2008. Вып. 6 (171). С. 83–91.

- Даниленко В. Н., Лысенков А. И., Чугунов А. В. и др. Применение спектрометрии естественного гамма-излучения для решения прикладных задач // Скважинные нефтяные технологии на рубеже веков. Уфа: ОАО НПП «ВНИИГИС», С. 111–138.

- Добрынин В. М., Вендельштейн Б. Ю., Кожевников Д. А. Петрофизика. М.: Недра, 1991. 368 с.

- Кнеллер Л. Е., Гайфуллин Я. С., Рындин В. Н. Автоматизированное определение коллекторских свойств, нефтегазонасыщенности по данным каротажа (петрофизические модели и методы). М.: ВИЭМС, 1990. 73 с.

- Кожевников Д. А. Гамма-спектрометрия в комплексе геофизических исследований нефтегазовых скважин. Методическое пособие (Часть I) // НТВ «Каротажник». Тверь: Изд. АИС. 1997. Вып. 38. С. 39–76.

- Кожевников Д. А. Гамма-спектрометрия в комплексе геофизических исследований нефтегазовых скважин. Методическое пособие (Часть II) // НТВ «Каротажник». Тверь: Изд. АИС. 1997. Вып. 39. С. 37–67.

- Лысенков А. И. Хлорный каротаж на базе стационарных нейтронных источников // НТВ «Каротажник». Тверь: Изд. АИС. 2006. Вып. 7–8. С. 109–128.

- Перелыгин В. Т., Даниленко В. Н., Лысенков А. И. и др. Обеспечение промышленной безопасности объектов подземного хранения газа ОАО «Газпром». Результаты работ в 2010 г. и ход выполнения в 2011 г. // Материалы совещания, 2011 г. М.: ООО «Газпром экспо», 2012. 216 с.

- Сиразетдинов И. Т., Гайфуллин Я. С., Ильясова М. И., Шайхутдинова Р. А. Прогноз техногенного кавернообразования в скважинах с учетом литологической информации // НТВ «Каротажник». Тверь: Изд. АИС. 2019. Вып. 1 (295). С. 38–47.

- Сиразетдинов И. Т., Ильясова М. И., Гайфуллин Я. С. Достоверность оценки объемной литологической модели в обсаженных скважинах в условиях дефицита геолого-геофизической информации // НТВ «Каротажник». Тверь: Изд. АИС. Вып. 5 (287). С. 83–93.

Рецензент доктор геол.-минер. наук, проф. Ю. И. Кузнецов