The equipment was development by AO NPP VNIIGIS in cooperation with AO NPF GITAS

SCOPE OF APPLICATION

Casing string and tubing integrity monitoring in killed and non-killed oil and gas wells of multi-string structure

FEATURES AND ADVANTAGES

In newly drilled wells MID-4 tool is used for monitoring:

- well design up to five casing barriers evaluation

- compliance with the project of casing string set point with different diameters and wall thickness

- liner setting interval

- casing integrity and degree of wear during tool operation

In operating wells the MID-4 tool makes it possible to determine:

- perforation intervals

- location of through defects

- parting of casing in four-string structure

- actual installation intervals of sealing patches

- actual installation depth of casing packers, etc

- well design up to five casing strings

- corrosion intervals and degree of casing string wear

- intervals of casing defects for repair

- thickness of the 1st, 2nd, 3rd, and 4th columns

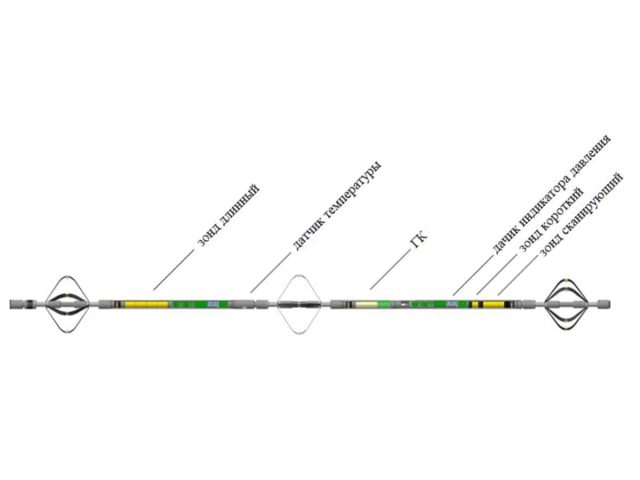

The tool includes 3 probes of defectoscope-thickness gauge, highly sensitive temperature sensor, gamma-ray and pressure sensors.

Specifications

| Max.diameter of the investigated pipes, mm исследуемых труб, мм | 508 |

| Number of investigated pipes | 1; 2; 3; 4 |

| Min.diameter of the investigated pipe, mm | 60 |

| Max.total thickness of four barriers, mm | 50,8 |

| Measurement accuracy of pipe wall thickness, mm first barrier second barrier third barrier fourth barrier | ±0,5 ±0,7 0,15 times the barrier thickness 0,2 times the barrier thickness |

| Min.length of a defect “crack” type along the pipe axis, mm single pipe second pipe third barrier fourth barrier | 1/12 of the perimeter 1/4 of the perimeter 1/3 of the perimeter 1/2 of the perimeter |

| Min.length of a defect “transverse crack” type for a single pipe | 1/7 of the perimeter |

| Temperature sensor resolution, °С | 0,01 |

| Time constant of the thermometer, sec. | 0,5 |

| Operation temperature, °С | -10 to 150 |

| Max.temperature rating, MPa | 100 |

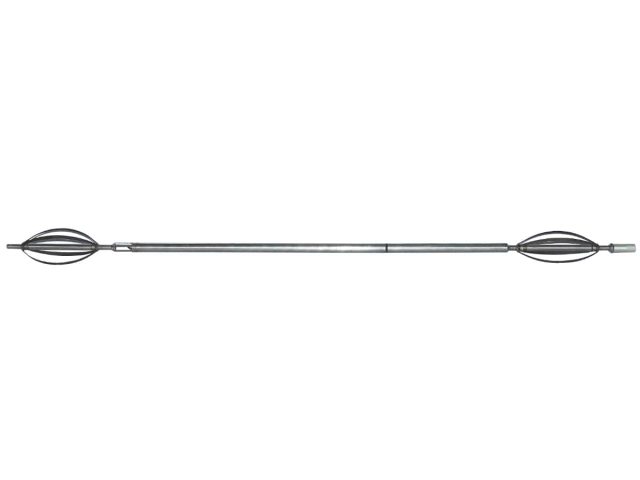

| Overall dimensions of tool, mm: - diameter / length | 42/6735 |