Development of AO NPF GITAS with PAO GAZPROM

SCOPE OF APPLICATION

Cased wells with OD of not more than 180 mm, through tubing with ID of not less than 60 mm, with the total thickness of the evaluated strings up to 30 mm, with the maximum bottomhole temperature of 120 °С and the maximum hydrostatic pressure of 80 MPa.

FEATURES AND ADVANTAGES

The complex is designed for monitoring of casing, tubing and annulus integrity during industrial safety expert review of non-killed wells through tubing without putting the well out of operation. This complex enable:

- to perform cement placement evaluation in operating gas wells;

- to identify induced caverns in the producing gas reservoirs;

- to detect behind-the-casing and annulus accumulations of gas;

- to determine gas saturation Sg of formations;

- to create a lithological model of wells.

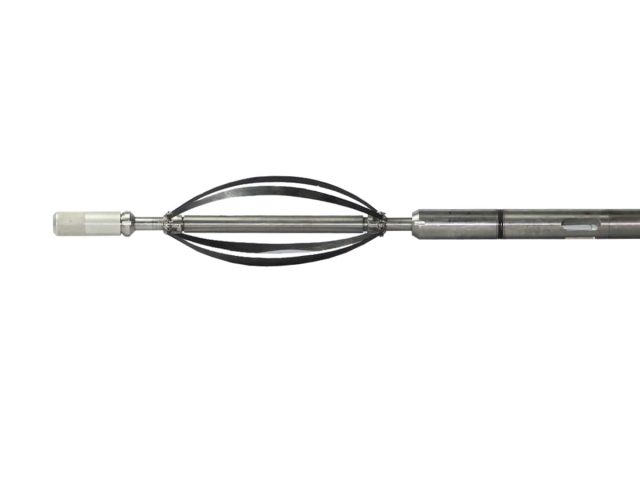

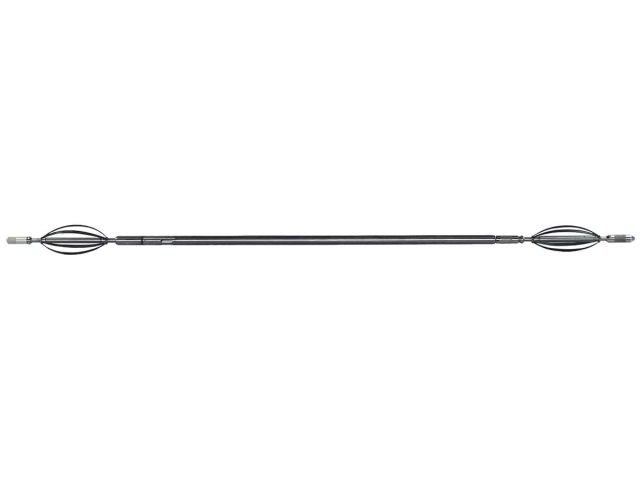

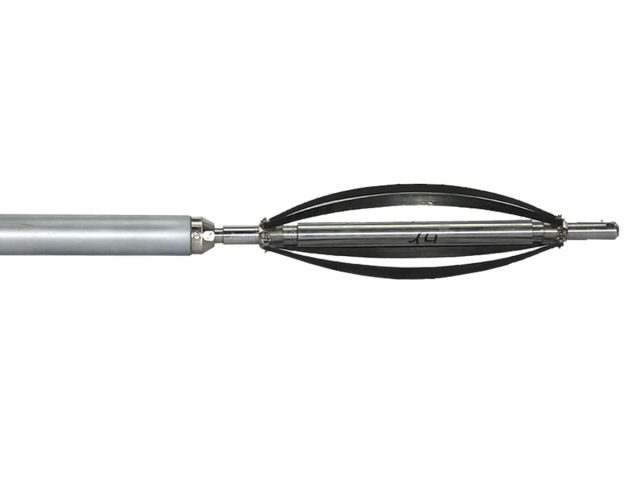

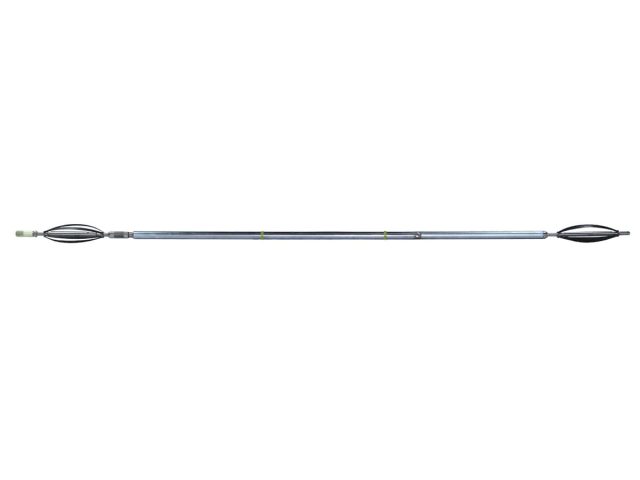

The downhole toolstring OTSK-OSZP consists of two modules with the possibility of both independent and combined operation. The upper module (OTSK tool) consists of a SGR probe, a scanning magnetic-pulse defectoscope, a thermometer and a pressure gauge. The lower module (OSZP tool) consists of two thermal neutron (NNL) probes disposed below the sealed fast neutron source (FNS) and three probes of wide-range induced spectral neutron gamma-ray logging (SNGR-Sh) located above the FNS.

This slim equipment was tested in oil and gas fields of Russia, Germany, Kazakhstan, etc.

| Operation conditions | |

| Max.pressure, MPa | 80 |

| Temperature range | from +5 оС to +120 оС |

| Logging cable, number of conductors | 1–3 |

| Max. length of single-conductor cable | up to 5 km |

| Surface equipment | |

| Data transmission | Manchester-2 |

| Data transmission speed, Mbaud | 1/48 |

| Supply current of downhole tool, mA | max 250 |

| Power supply | 180–260V, 50Hz |

| Consumed power, W | max 30 |

| Dimensions, length x width x height, mm: | 330 x 270 x 75 |

| Weight, kg | 4 |

| Relative humidity, % | max 98 |

| Atmospheric pressure, kPa (mm Hg) | 60-106 (450-800) |