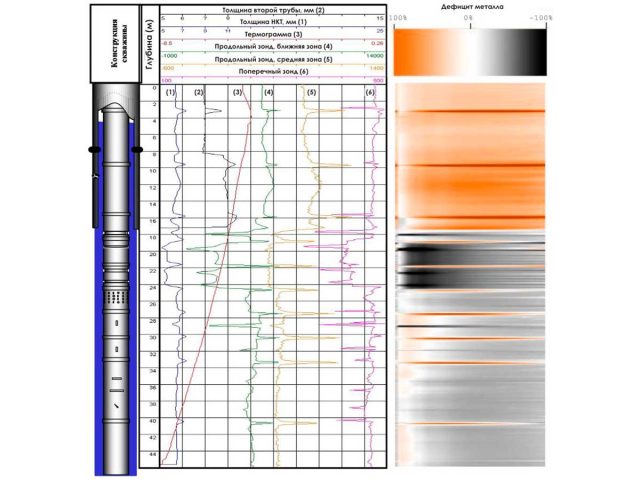

is designed to control technical condition of tubing, casing pipes and well strainer by a complex of methods including defectoscope and thickness measuring tool, highly sensitive thermometer, gamma-ray logging and pressure sensor.

In most drilling wells MID-K-GK is used to control:

- well construction having till 4 casings;

- compliance to casing interval project with different diameter and wall thickness;

- tail liner installation interval;

- casing integrity and rate of wear during tool operation.

In the running wells MID-K-GK allows to define:

- perforation intervals;

- cut through failure position;

- casing blowout in double casing string well program;

- factual installation intervals of sealing patch;

- factual installation depth of casing packer and etc.;

- well construction till 4 casings;

- corrosion intervals and casing rate of wear;

- casing failure intervals, requiring repair;

- first, second and third casing thickness.

Specifications

| Pipe maximum diameter, mm | 324 |

| A single-pipe wall thickness measurement error, mm: for single pipes 2.5” for single pipes 5” | 0.4 0.5 |

| Through-tubing casing 5" wall thickness measurement error, mm | 0.7 |

| Minimum length of a “crack”-type detectable defect along the pipe axis, mm: for single pipes 2.5" for single pipes 5" for casing pipes 5" through-tubing measurement | 30 50 70 |

| Minimum length of a “transversal crack”-type detectable defect | 1/6 of the perimeter |

| Thermometer resolution, °С | 0.01 |

| Thermometer time constant, sec | 0.5 |

| Maximum operating temperature, °С | 120, 150, 175 |

| Maximum operating pressure, MPa | 100 (110) |

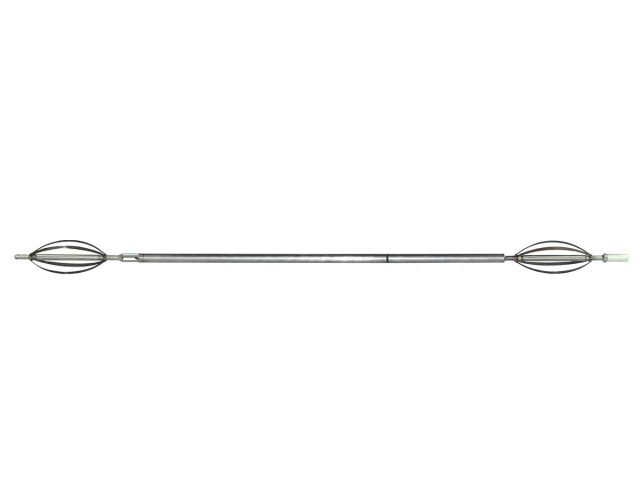

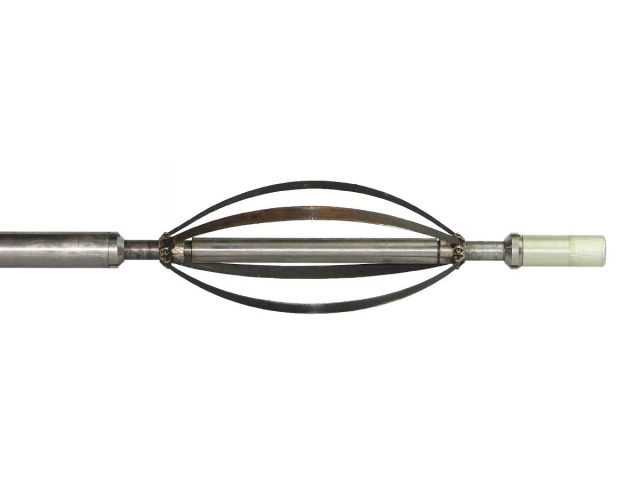

| Downhole dimensions, mm: diameter length | 42 2595 |

| Weight, kg | 9 |

| Power consumption, W | up to 4 |