is designed to control technical condition of steel tubing and pump and compressor string in unkilled gas and oil wells of single-column and columned constructions, perforation interval specification.

Features and Advantages

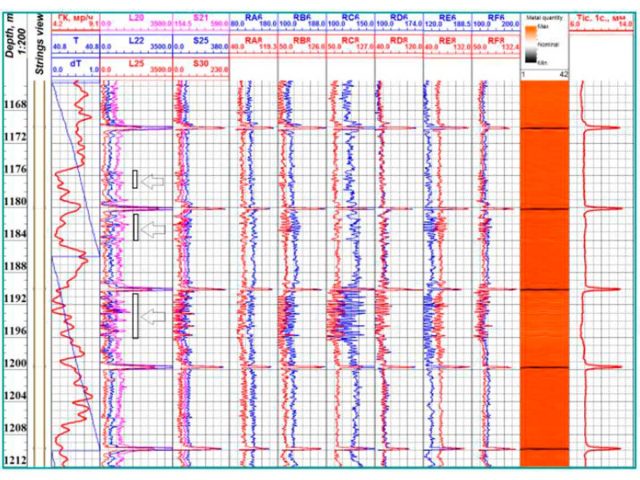

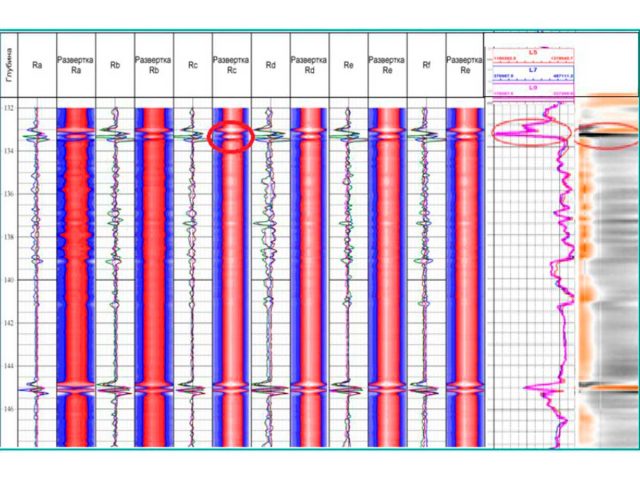

- the possibility of two pipes defectoscopy and thickness gauging performance with pipe wall thickness change value and their transverse and longitudinal defects*;

- the possibility of columned well construction determination (up to 4 pipes);

- high-sensitive thermometer and GK presence for according to depth.

Apparatus composition

- digital downhole tool with two centering devices, surface interface block with power supply, software, control and monitoring station;

- operates with computer of Notebook type (mobile variant) or in the composition of any software-controlled logging station.

Specifications

| Pipe maximum diameter, mm | 324 |

| Thermometer resolution, °С | 0.01 |

| Thermometer time constant, sec | 0.5 |

| A single-pipe wall thickness measurement error, mm: for single pipes 2.5" for single pipes 5” | 0.3 0.4 |

| Through-tubing casing 5" wall thickness measurement error, mm 5” | 0.7 |

| Minimum length of a “crack”-type detectable defect along the pipe axis, mm: for single pipes 2.5" for single pipes 5" for casing pipes 5" through-tubing measurement | 14 30 70 |

| Minimum length of a “transversal crack”-type detectable defect | 1/6 of the perimeter |

| Maximum operating temperature, °C | 120 (150) |

| Maximum operating pressure, MPa | 100 (120) |

| Downhole dimensions, mm: diameter length (including centralizers and GR module) | 42 2595 |

| Weight, kg | 9 |

*high radial and azimuthal resolution